SAND CASTING METHOD

Sand casting is the most common system. Silica sands agglomerated with self-hardening resins and/or silicates are used. It is usually used to produce mechanical parts of all types, in particular pump bodies, valves, rings, supports and plates. It is compatible with all types of steels and alloys and requires equipment consisting of a model, traditional core boxes in wood or resin.

We produce single pieces or small series.

STEEL CASTINGS FOR HYDROELECTRIC PLANTS

Hub

Mat: 1.4313 GX5CRNI13-4

Weight: 250 kg

Nozzle

Mat: G20MN5

Weight: 500 kg

Wicket gate

Mat: 1.4317

Weight: 50 kg

Deflectors

Mat: ASTM A743 CA-6NM

Weight: 60 kg

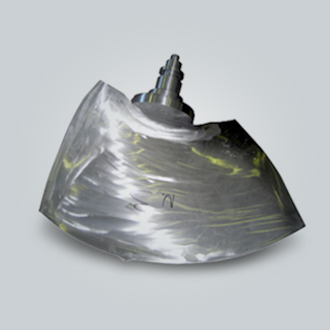

Kaplan blade

Mat: 1.4317

Weight: 40 kg

Wicket gate

Mat: 1.4317

Weight: 130 kg

Runner hub

Mat: 1.4317

Weight: 175 kg

Deflectors

Mat: 1.4317

Weight: 20 kg

STEEL CASTINGS FOR THERMOELECTRIC POWER PLANTS

Strut

Mat: GX12CrMoWVNbN10-1-1

Weight: 80 kg

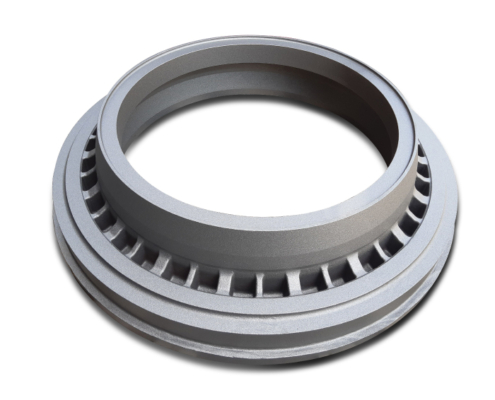

Ring

Mat: GX12CrMoVNbN9-1

Weight: 420 kg

STEEL CASTINGS FOR THE OIL & GAS INDUSTRY

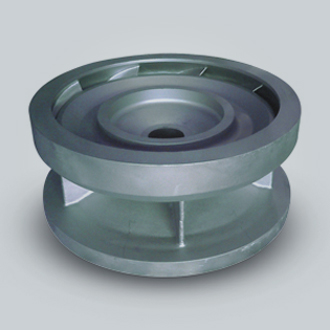

Impeller

Mat: ASTM A995 GR.6A

Weight: 300 kg

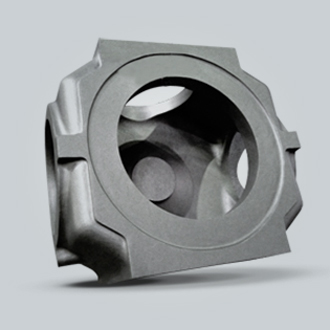

Pump casing

Mat: ASTM A743 CF-3M

Weight: 200 kg

Casing

Mat: ASTM A890 Duplex GR.6A

Weight: 60 kg

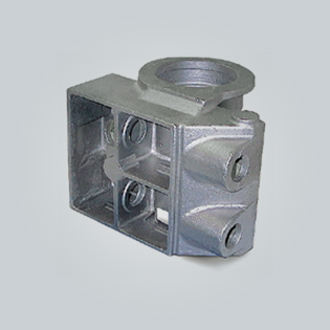

Bearing bracket

Mat: ASTM A216 WCB

Weight: 10 – 100 kg

Diffuser

Mat: ASTM CF 3M

Weight: 155 kg

Valve casing

Mat: ASTM A216 WCB

Weight: 100 kg

Diffuser casing

Mat: ASTM A743 CA6NM

Weight: 250 kg

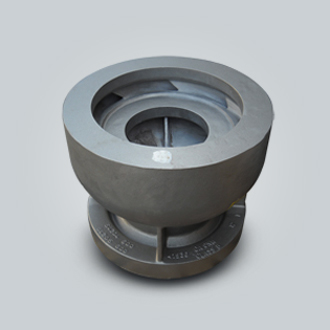

Suction bell

Mat: ASTM A890 GR.6A

Weight: 150 kg

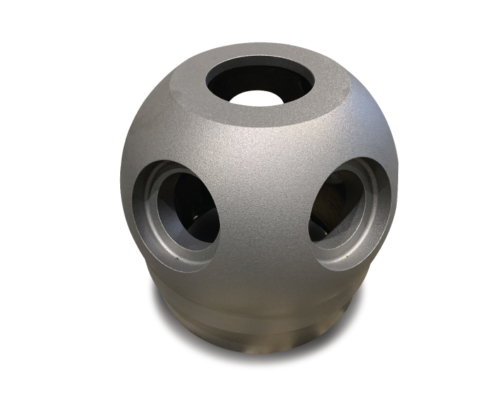

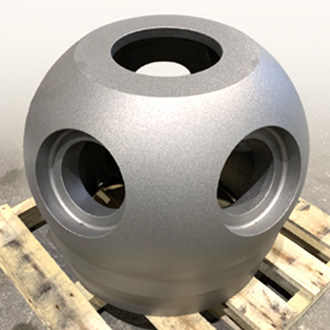

Bowl

Mat: ASTM A890 GR.6A

Weight: 250 kg

Diffuser casing

Mat: ASTM A216 WCB

Weight: 250 kg

Valve body

Mat: ASTM A216 WCB

Weight: 200 kg

Valve casing

Mat: ASTM A216 WCB

Weight 15 kg

Pump casing

Mat: ASTM A890 Duplex GR.6A

Weight: 780 kg

Distributor casing

Mat: ASTM A4P4 CNGHC

Weight: 35 kg

Suction cover

Mat: A995 Duplex Gr.6A

Weight: 180 kg

Impeller

Mat: ASTM A351 CK3MCuN

Weight: 70kg

Casing

Mat: ASTM A216 WCA

Weight: 260 kg

Bearing case

Mat: A890 Duplex Gr.6A

Weight: 37 kg

Impeller double aspiration

Mat: ASTM A216 WCB

Weight: 545 kg

STEEL CASTINGS FOR FOOD AND BEVERAGE

Casing

Mat: ASTM A743 CF-8M

Weight: 20 kg

Pump casings

Mat: ASTM A743 CF-8M

Weight: 25 kg

Casings

Mat: Martensitic stainless steel

Weight: 15 kg

Auger

Mat: Austenitic stainless steel

Weight: 80 kg

Bracket

Mat: ASTM A743 CF-8M

Weight: 70 kg

STEEL CASTINGS FOR THE ECOLOGICAL SECTORS

Casing

Mat: ASTM A743 CF-8M

Weight: 20 kg

Pump casings

Mat: ASTM A743 CF-8M

Weight: 25 kg

Casings

Mat: Martensitic stainless steel

Weight: 15 kg

Auger

Mat: Austenitic stainless steel

Weight: 80 kg

Bracket

Mat: ASTM A743 CF-8M

Weight: 70 kg

STEEL CASTINGS FOR OTHER SECTORS

Mechanical Components

Mat: A743 CA-6NM

Weight: 1250 kg

Casins

Mat: Low Carbon Steel

Weight: 290 kg

Water chambre

Mat: Austenitic

Weight: 500 kg

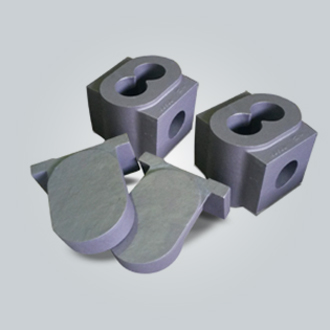

Components for extrusion pump

Mat: A743 CA-6NM

Weight: 2-200 Kg

Casing

Mat: ASTM A216 WCB

Weight: 30 kg