CERAMIC CASTING METHOD

Ceramic casting uses monolithic shapes and cores made of refractory materials, which are subsequently treated. It is an ideal process for conditions where constancy and dimensional accuracy are required, the obtainment of surfaces with reduced roughness, thicknesses and allowances and the almost total absence of blowholes and inclusions.

It allows an excellent structural compactness, therefore it improves the mechanical characteristics and resistance to corrosiveabrasive environments /fluids and atmospheres. It is interesting for parts with surfaces that cannot be machined qualitatively and superficially, and excellent as cast. It is advantageous in cases where alloys with critical hardness and machinability, considering the reduced allowances and subsequent less laborious mechanical machining, in some cases superfluous. Better metallurgical integrity, excellent surface finish and good dimensional accuracy make the ceramic process highly elastic in use, allowing greater

design flexibility.

Normally this process is used to produce impellers for centrifugal pumps, impellers for compressors, diffusers for pumps, rotors for turbines, Pelton wheels, pelton blades, Kaplan blades, parts for the food industry, special pump bodies, nautical and agitator propellers, molds for forging, range, plastics, glass, die casting molds, dies and punches, extrusion dies, tube bending spindles, filter press plates, various pieces for the chemical, mechanical, naval and aeronautical industries

The models, conceptually of a traditional type, are built with remarkable accuracy and precision

STEEL CASTINGS FOR HYDROELECTRIC PLANTS

Francis single aspiration

Mat: ASTM A743 CA-6NM

Weight: 500 kg

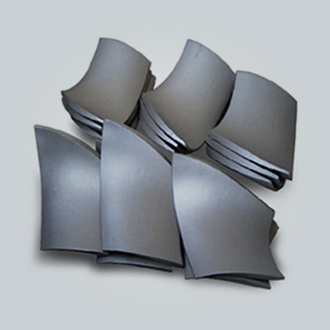

Francis blades

Mat: ASTM A743 CA-6NM

Weight: 3 kg

Pelton blades

Mat: 1.4317 GX4CrNi13-4

Weight: 15 kg

Pelton runner

Mat: ASTM A743 CA-6NM

Weight: 400 kg

Francis single aspiration

Mat: 1.4317 GX4CrNi13-4

Weight: 600 kg

Francis double aspiration

Mat: 1.4317 GX4CrNi13-4

Weight: 900 kg

Pelton runner (dye penetrant test)

Mat: 1.4317 GX4CrNi13-4

Weight: 520 kg

Francis single aspiration

Mat: 1.4317 GX4CrNi13-4

Weight: 800 kg

Francis runner single aspiration

Mat: ASTM A743 CA-6NM

Weight: 1100 kg

Francis runner single aspiration

Mat: ASTM A743 CA-6NM

Weight: 1100 kg

Francis single aspiration

Mat: ASTM A743 CA-6NM

Weight: 700 kg

Pelton runner

Mat: ASTM A743 CA-6NM

Weight: 1300 kg

STEEL CASTINGS FOR THERMOELECTRIC POWER PLANTS

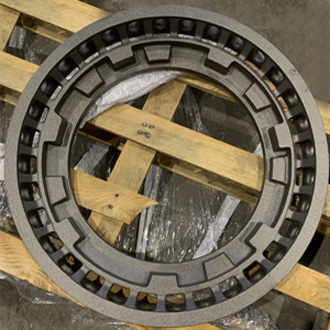

Ring

Mat: Martensitic stainless steels

Weight: 70 kg

Inner ring

Mat: Martensitic stainless steels

Weight: 90 kg

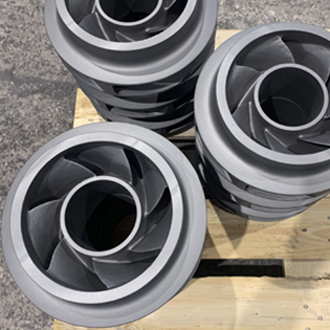

STEEL CASTINGS FOR THE OIL & GAS INDUSTRY

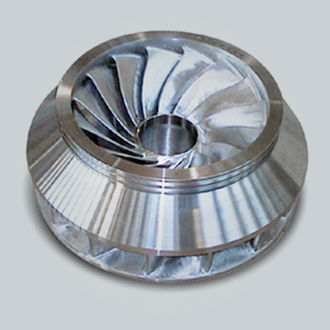

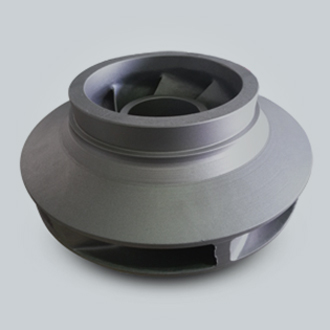

Compressor impeller

Mat: ASTM A743 CF317

Weight: 700 kg

Impeller single asp.

Mat: A890 Duplex GR.5A

Weight: 200 kg

Impeller single aspiration

Mat: A890 Duplex GR.6A

Weight: 250 kg

Cover casings / impeller

Mat: 1.4408

Weight: 25 – 50 kg

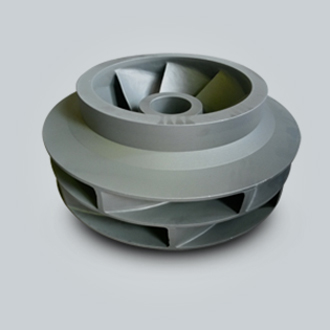

Impeller double aspiration

Mat: ASTM A743 CA-6NM

Weight: 350 kg

(Monolitic core)

Impeller single aspiration

Mat: ASTM A890 Duplex GR.5A

Weight: 15 kg

(Monolitic core)

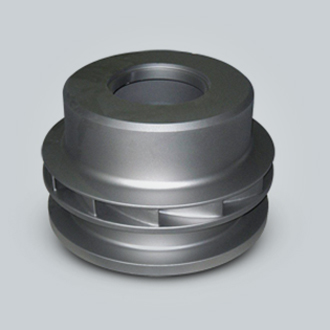

Compressor impeller

Mat: Austenitic/Nickel-Alloy

Weight: 100 kg

Diffuser

Mat: 1.4317

Weight: 250 kg

Diffuser

Mat: ASTM A890 GR.6A

Weight: 150 Kg

Impeller

Mat: ASTM A995 S.Duplex Gr.6A

Weight: 20 kg

Impeller superfinishing

Diffuser

Mat: ASTM A351 CN7M

Weight: 20 kg

Diffuser

Mat: ASTM A743 CA6NM

Weight: 400 kg

Compressor impeller

Mat: ASTM A494 CU5MCUC/ASTM

A743 CF-8M

Weight: 150 kg

Impeller double aspiration

Mat: ASTM A487 CA-6NM Gr.A

Weight: 140 kg

Impeller double aspiration

Mat: 1.4317 GX4CRNi13-4

Weight: 380 kg

Diffuser

Mat: ASTM A743 CA-6NM

Weight: 30 kg

Impellers single aspiration

Mat: ASTM A995 Gr.6A

Weight: 25 kg

Impellers

Mat: ASTM A995 Gr.5A

Weight: 10 kg

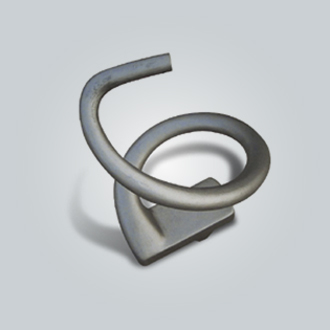

STEEL CASTINGS FOR FOOD AND BEVERAGE

Propeller

Mat: Austenitic stainless steel

Weight: 2 kg

Mixing propeller

Mat: Austenitic stainless steel

Weight: 240 kg

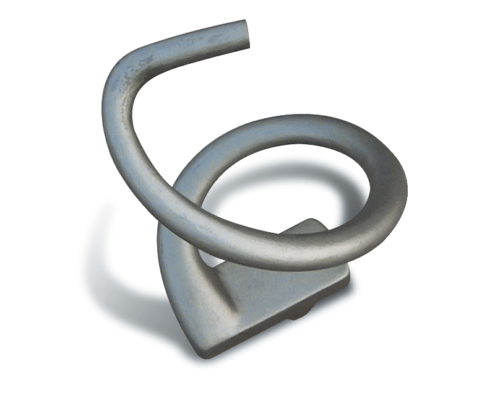

Spiral kneader

Mat: Austenitic stainless steel

Weight: 17 kg

Fluid accelerator

Mat: Austenitic stainless steel

Weight: 60 kg

Impeller

Mat: Austenitic stainless steel

Weight: 10 kg

Casing

Mat: Austenitic stainless steel

Weight: 10 kg

Casings

Mat: Austenitic stainless steel

Weight: 50 kg

STEEL CASTINGS FOR THE ECOLOGICAL SECTORS

Impeller pump

Mat: Stainless steel

Weight: 25 kg

Impeller pump

Mat: Martensitic S.S / Austenitic

Weight: From 20 up to 80 kg

Open Impellers

Mat: ASTM A351 CK3MCuN

Weight: 40 kg

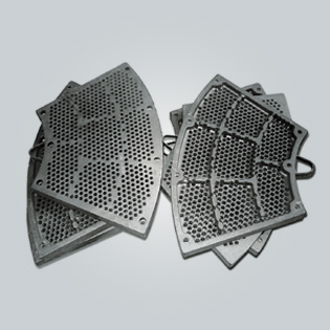

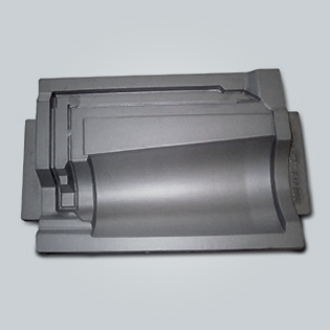

STEEL CASTINGS FOR OTHER SECTORS

Cover casings (Shipbuilding

industry)

Mat: CA-6NM

Weight: 60 kg

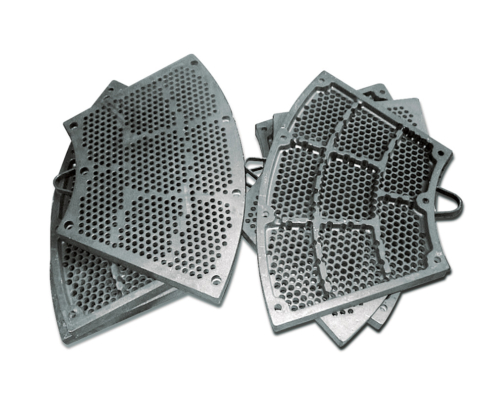

Perfored components

(Mechanical sectors)

Mat: A743 CA-6NM

Weight: 45 kg

Hydrojets

Mat: ASTM A890 Duplex Gr.4A

Weight: 70 kg

Mold (Construction sector)

Mat: Austenitic stainless steel

Weight: 80 kg

Mold (Construction sector)

Mat: Austenitic stainless steel

Weight: 80 kg

Art of a die

Mat: ASTM A743 CF-8

Weight: 20 kg

(Monolithic core)

Hydrojets

Mat: ASTM A743 Duplex Gr.4A

Weight: 110 kg

Rotor e stator

Mat: ASTM A747 CB7-Cu1

Weight: 100-300 kg

Plugs

Mat: ASTM A747 CB7-Cu1

Weight: 20 kg

Impellers

Mat: GX6CRNIMO1810

Weight: 30 kg