PLANTS AND PROCESSES

GSA covers an area of approximately 11,300 square meters of which 6200 square meters are covered and used for offices, production, warehouses and testing.

TECHNICAL AREA

Thanks to many years of experience and the use of modern systems, our technicians are able to guarantee an high level of casting quality right from the design stage. Thanks to the collaboration with SAFAS, through magmasoft, we are able to simulate the filling and solidification of our products in order to minimize the critical areas of the castings. Then, with the collaboration of external pattern shops of proven reliability, we can create patterns and molds, both using artisan workshops, and using machining centers and rapid prototyping printers.

FOUNDRY AREA

We can produce the castings through 3 different systems, based on casting characteristics and customers need.

STEEL MILL AREA

GSA has 3 induction melting furnaces of capacity 1000 and 350 kg that can work in combination for a maximum capacity of 2000 kg.

Great experience and versatility mean that the range of steels that GSA is able to produce is very wide. Precisely for this reason the material used for the castings is always selected and of the highest quality.

FINISHING AREA

The casting finishing area includes: cutting and flatting areas with welding, grinding and finishing boxes, as well as hand sandblasting boxes, and various heat treatment furnaces, areas and cooling tank for quenching, confer greater mechanical properties. In addition, GSA actively collaborates with the LAS company, also part of the SAFAS group specialized in grinding, welding and deburring for the finishing of the casts.

Mechanical processing: for mechanical operations, turning and milling, Gsa collaborates with various mechanical workshops and in particular with AMS, the workshop of the group.

Ams, in fact, is equipped with both traditional and numerically controlled machine tools capable of providing complete castings from mechanical machining of rough and / or finished castings, balanced, and ready for installation in operation.

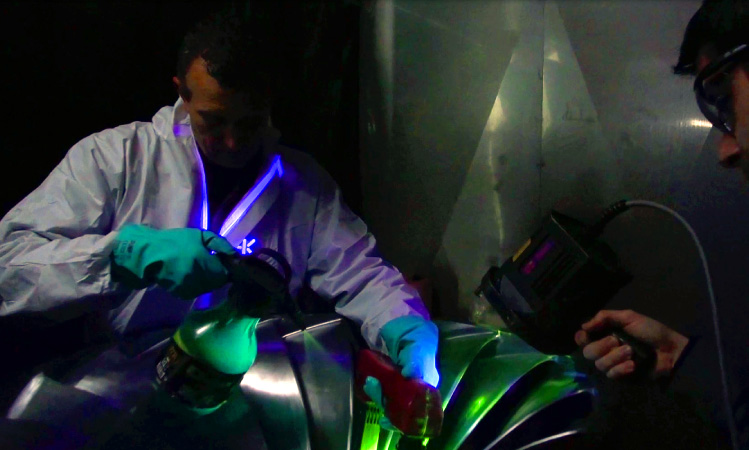

QUALITY CHECK AREA

Our technicians are committed to guaranteeing the quality of processes and products, in compliance with UNI standards. Our facilities allow us to internally perform the quality controls and tests required even for castings with complex conformities. In some cases, for particularly demanding requests, GSA makes use of the equipment of the parent company Safas.

MODELING AND MODELS WAREHOUSE

All patterns are cataloged and stored in a covered warehouse. Small adjustments and maintenance are carried out by our model shop.

GSA PARTNERS

GSA has built a solid network of selected partners such as mechanical workshops, pattern shop, studios and external laboratories for its offer of services, such as the creation of models and molds, prototyping, technical consultancy, and increasing the quality of the castings.