LOST WAX CASTING METHOD

The particularity of the process and the characteristics of the ceramic materials used for the shape favor the reproduction of the finest details and little thicknesses, with surface roughness better than 3.2 Ru, narrow dimensional tolerances and good metallurgical properties. It can be used for all steels, alloys and super alloys and has fewer geometry limitations than other systems.

By injecting semi-liquid wax, the model of the casting to be made is obtained from an aluminum mold. Then, by immersing one or more models assembled around a central support in a particular ceramic mixture, a shell is created with a thickness capable of resisting the metallostatic pressures of the alloy. After drying of the coating, the wax is evacuated in an autoclave and the whole is ceramicized at a high temperature. It is then be poured with the hot form.

Parts can be made for various markets, we mainly supply impellers, vanes, supports, bodies, complex mechanical parts.

STEEL CASTINGS FOR HYDROELECTRIC PLANTS

Wicket gate

Mat: A743 CA-6NM

Weight: 12 kg

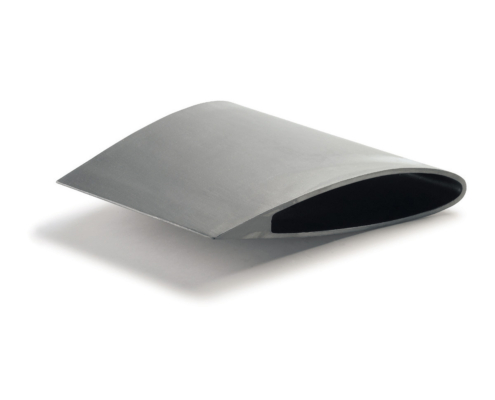

Pelton blade

Mat: ASTM A743 CA-6NM

Weight: 1 kg

STEEL CASTINGS FOR THERMOELECTRIC POWER PLANTS

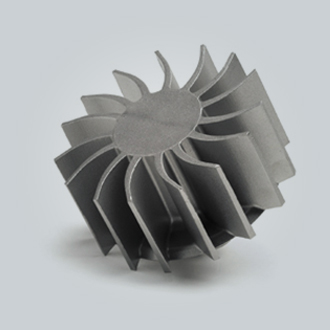

Impeller

Mat: Nickel Alloy

Weight: 3 kg

Strut

Mat: 1.4405 GX4CrNiMo16-5-1

Weight: 80 kg

Strut

Mat: GX5CrNiMo19-11-2

Weight: 26 kg

STEEL CASTINGS FOR THE OIL & GAS INDUSTRY

Vacuum pump impeller

Mat: ASTM A743 CF-8M

Weight: 7 kg

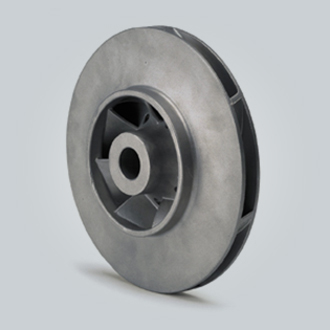

Impeller single asp

Mat: A890 Duplex GR.5A

Weight: 38 kg

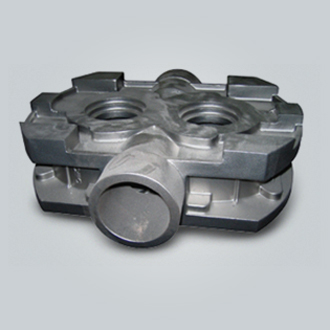

Vacuum pump casing

Mat: CF-8M

Weight: 30 kg

Vacuum pump impeller

Mat: GX6CRNiMO1810

Weight: 18 kg

Propeller

Mat: A743 CF8M / A890 Duplex GR.5A

Weight: 18 kg

Impeller single aspiration light 8

Casing pumps

Mat: CWI2MW

Weight: 15 kg

Pump casing

Mat: A763 CF8

Weight. 6 kg

Vacuum pump impeller

Mat: ASTM A743 CF-8M

Weight: 7 kg

Gas separator

Mat: CU5MCUC/DUPLEX/S.

DUPLEX

Weight: 1 kg

STEEL CASTINGS FOR FOOD AND BEVERAGE

Pump casing

Mat: ASTM A743 CF-8M

Weight: 15 kg

Pump casing

Mat: Austenitic stainless steel

Weight: 8 kg

Flat Beater

Mat: Austenitic stainless steel

Weight: 3 kg

Pumps covers

Mat: ASTM A743 CF-8M

Weight: 5 kg

Casing

Mat: Austenitic stainless steel

Weight 3 kg

Auger / Casing

Mat: Austenitic stainless steel

Weight: 6 kg

Casing

Mat: Austenitic stainless steel

Weight: 5 kg

Covers

Mat: Austenitic stainless steel

Weight: 4 kg

STEEL CASTINGS FOR THE ECOLOGICAL SECTORS

Plate holder

Mat: AST A216 WCB

Weight: 3 kg

Bracket

Mat: FeG 70 / A890 Duplex Gr.4a

Weight: 7 kg

Impeller side / shield

Mat: Austenitic stainless steel

Weight: 10 kg

Impeller

Mat: Austenitic stainless steel

Weight: 5 kg

Bracket

Mat: Austenitic stainless steel

Weight: 40 kg

Plate holder

Mat: ASTM A747 CB7CU1

Weight: 6 kg

Levers

Mat: Austenitic stainless steel

Weight: 2 kg

Mechanical component

Mat: Austenitic stainless steel

AusteniticWeight: 2 kg

STEEL CASTINGS FOR OTHER SECTORS

Levers, deflectors

Mat: 1.4408

Weight: 3 kg

Gear pump components

Mat: GX4CRNI13-4

Weight: 20 Kg

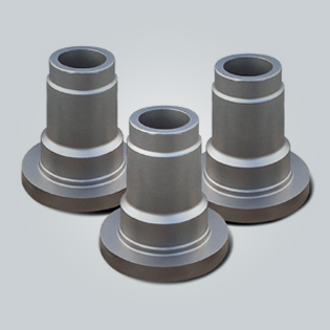

Bushes

Mat: A743 CF-8M, A743 CA-6NM

Weight: 12 kg

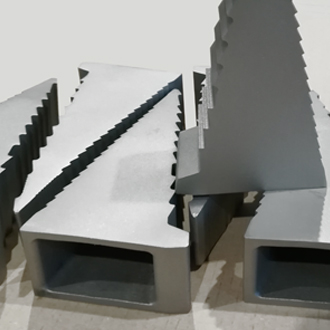

Blades

Mat: A216 WCB

Weight: 14 kg

Gear pump components

Mat: GX4CRNI13-4

Weight: 2 Kg

Brackets

Mat: A743 CF-8M

Weight: 6 Kg

Component (roadside assistance)

Mat: 42CRMO4

Weight: 1,5 kg

Pumps

Mat: A890 Duplex Gr.4A

Weight: 8 kg