NON-DESTRUCTIVE TEST

Gsa produces every single cast under a quality guarantee, an intrinsic value of ours. Each of our products is meticulously checked to verify its integrity and compliance with current regulations. Quality controls on products are conducted in compliance with international standards through rigorous internal procedures prepared according to customer requests.

The CND Laboratory is managed by qualified 3rd level personnel according to UNI EN ISO 9712, in accordance with American and European standards. The laboratory management system is recognized by various certification bodies, as well as by major national and foreign companies. The final tests are completed by qualified 2nd level EN and ASNT CIA operators, as well as state-of-the-art equipment subjected to rigorous periodic inspections.

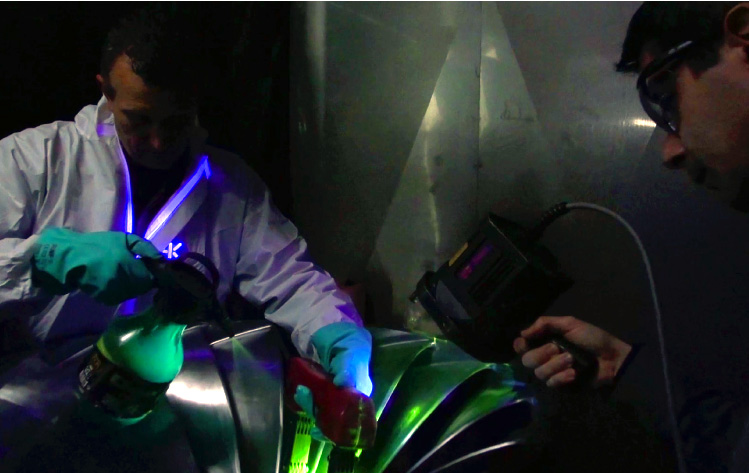

MT inspection

Magnetic control for the detection of surface and subsurface defects in ferromagnetic materials, using the dry, wet, wet fluorescent method in controlled conditions of ambient

brightness.

MAGNAFLUX apparatus for examination with dry and wet magnetic powders, fluorescent in Wood’s lamp.

UT inspection

Ultrasonic inspection with USN 60 digital computerized device, supplied by GE and equipped with straight, angled and focused

probes, in order to define the state of integrity of the parts and components, even inside them, establishing depth, nature, extent and position of any discontinuities and defects.

LP inspection

Contrast and fluorescent penetrating liquids control, according to European and American standards. Nuclear certifications of

products used in controlled conditions of ambient light.

RX inspection

Radiographic X-ray inspection is performed at the parent company Safas, with Seifert 200Kv equipment and Linatron

M9A Dual Energy linear accelerator of 9 ÷ 5 Mev (gamma rays with two sources IR 196 and Co 60).

VT inspection

Visual inspection of the castings by our second and third level technicians.